SIMS Pump offers “TECHNOLOGY UPGRADES” for new, or existing pumps. SIMS Pump has the ability to make any centrifugal pump Energy Efficient and Long Lasting. SIMSITE® Pumps, Impellers & Rings, and Pump Parts Out-last and Out-perform traditional metallic pumps by many years! All SIMSITE® Pumps and pump components improve performance, longevity, efficiency. They also eliminate corrosion, erosion, & cavitation problems!

SIMSITE® is a trade name for a group of patented structural composite Pumps, Impellers & Other Pump Parts manufactured and offered exclusively by SIMS PUMP Valve Company, Inc.

Because of SIMSITE®’s excellent mechanical properties, it is one of the strongest composites on the market today.

SIMSITE® Products are light weight, energy efficient, and stand up much better to erosion, cavitation, and corrosive environments than metallic parts & pumps.

SIMSITE® Products outlast and outperform other products on the market, and will therefore significantly improve performance, reliability, longevity, and savings!

SIMSITE® Products Never Corrode in Seawater, Waste Water, River Water, or Chlorinated water and have excellent corrosion resistance to most chemicals.

Because SIMSITE® Products are completely machined from solid blocks of SIMSITE® structural composite, they have excellent mechanical strength and are not subject to internal voids, cracks, or imperfections like cast or molded products!

SIMSITE® structural graphite composites have continuously interwoven fibers in a tri-dimensional weave throughout the composite, which gives all Simsite® products excellent Mechanical Properties & Strength, Durability, and Longevity.

Simsite® Products are NOT cast, or molded and therefore are not subject to casting defects and porosity.

SIMS manufactures SIMSITE® structural graphite composite computer engineered and generated pumps and pump parts (Impellers, Casing Rings, Wear Rings, Sleeves, Bushings, Mechanical Seals, Backplates, Shafts, Complete Volute Pump Casings, etc.), and many other structural components which are 100% machined on 5 to 8 axis robotic machining centers. SIMS uses state-of-the-art CFD techniques to engineer the vane geometries to maximize efficiency and performance specifically for the Customer’s System. SIMS can manufacture obsolete parts for any centrifugal pump with quick deliveries.

SIMS specializes in solving pump problems such as imbalance, cavitation, corrosion, electrolysis, erosion, and radial thrust problems. SIMS focuses on life extension, which is a very different concept from traditional pump manufacturers who make their money selling spare parts.

SIMS manufactures SIMSITE® Structural Graphite Composite Pumps, Pump Parts, Valves, and many other structural components, which are light weight, energy efficient, and stand up much better to corrosive environments, erosion, and cavitation than metallics, or other non-structural composites.

SIMSITE® Products outlast and outperform other products on the market, and will therefore significantly improve performance and reliability. Beyond performance, a look at total costs reveals that SIMSITE® Products are an exceptional added value. An evaluation of maintenance, spare parts, inventory, and energy usage, shows SIMSITE® Products to be the best option for most pump and valve applications.

Instead of repairing your pump, or replacing the old pump with a new pump of the same type, or quality, SIMS Pump Valve Company, Inc. (SIMS) offers better quality solutions, and much longer lasting products, and parts for Customers. With most pumps and pump parts coming directly, or indirectly from out of the Country, the reliability and quality of materials and parts for pumps and pumping systems have substantially deteriorated in the past few years forcing Customers to replace or repair products much more rapidly.

Fortunately today, there are specialized engineering companies like SIMS right here in the United States manufacturing machined structural engineered pumps, impellers, rings, sleeves, bearings, bushings, and mechanical seals, which are computer engineered, designed, and precision machined (not cast or molded) with the objective of maximizing longevity and reliability.

Beyond performance, a look at total costs reveals that SIMSITE® composite Pumps, Impellers and other pump parts are an exceptional added value. An evaluation of maintenance, spare parts, inventory, and energy usage, shows SIMSITE® Products to be the best option for almost all pump applications!

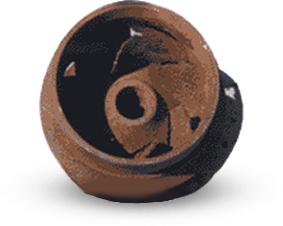

A Metallic Impeller after only 3 month of operation . This Impeller was subject to corrosion and cavitation attack .

The same Impeller in SIMSITE® after over a year of operation looks brand new .

Simsite®’s key benefits are its corrosion and erosion resistance, its cavitation resistance, its light weight (1/6 the weight of bronze) and it lasts 3-5 times longer than metallics. For more than 35 years SIMS has been manufacturing Simsite® pumps, impellers, bearings and rings of all sizes that exceed the performance of metallics in salt water and corrosive environments. Simsite®’s natural lubricity reduces wear on motors, bearings, and rings while providing quiet vibration free operation at a cost that is competitive with bronze.