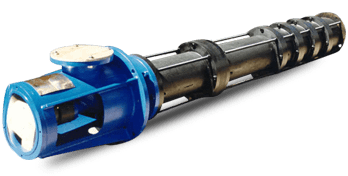

The SIMS Structural Composite Vertical Turbine Pumps are very different from any other pumps on the market.

The suction bell, casing bowls, diffusers, casing rings, guide bearings, bushings, and sleeves are completely machined on the outside as well as the inside from solid blocks of the patented SIMSITE® Structural Composite.

Casting imperfections, rough surfaces, alignment issues, corrosion, erosion, electrolysis, and cavitation problems are all eliminated with SIMSITE® Vertical Turbine pumps, which reduces turbulence and increases efficiency, performance, and longevity.

Like the SIMS Vertical Pit Pumps, the SIMS Vertical Turbine Pump has SIMSITE® Guide Bearings in these pumps which can take dry running at start up and will not melt, deform, seize like bronze, rubber, or thermoplastic bearings.

SIMSITE® Pump Bowls can be added, or subtracted from these pumps to meet your specific performance requirements.

Because SIMSITE® Pumps are machined (as opposed to being cast), they are engineered to meet the Customer’s specific design and operating performance requirements.

Each bowl and diffuser section is 100% precision machined from SIMSITE® insuring perfect alignment, and performance, which increases efficiency & longevity. SIMS manufactures pumps to meet YOUR needs as opposed to trying to match a general range pump to meet your requirements.