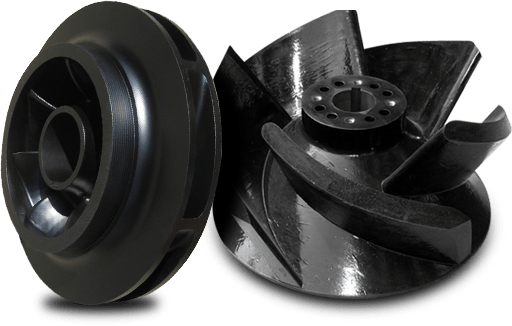

Impellers machined from Simsite® offer tremendous advantages over traditional impellers cast from metal. Simsite® Impellers are light weight, offer tremendous mechanical strength, and corrosion, erosion & cavitation resistance. Simsite® Impellers and Casing Rings have been used successfully since 1955 in the Marine, Navy and Industrial & Chemical markets. Simsite® Impellers outlast and outperform impellers manufactured from bronze, stainless steel, duplex steel, monel, and even titanium.

Because Simsite® Impellers are computer engineered, designed, and precision machined, the impeller vane geometry can be engineered to maximize efficiency and performance. Problems such as recirculation, radial thrust, and cavitation can be minimized, or eliminated by upgrading to Simsite® Impellers & Rings. Impeller vane shapes can easily be modified to provide the best vane shape for specific applications and performance requests.

It is all too common a problem – You purchased a pump for one specific performance and when you put the pump into service in your plant, or ship, the pump operates at another point completely different from the original design point (BEP – best efficiency point) of the pump because of your system requirements. In addition to being very inefficient, when you operate the pump away from the original design point or BEP, it causes a multitude of problems. These problems include excessive noise & vibration, shaft oscillation, cavitation, premature wear and failure of the mechanical seals, bearings, rings, sleeves and impellers. In extreme cases, the shaft will break.

Fortunately, these problems can be easily resolved by installing Simsite® Impellers & Rings, which have been re-engineered for your system requirements. Not only is the efficiency of the pump improved, but also the reliability and longevity of the complete pump is substantially improved!

LIGHT WEIGHT – The exceptional high strength-to-weight ratio of Simsite® permits a much lighter weight impeller. This means a substantial reduction in start-up load, longer bearing, ring, motor, and mechanical seal life, and less shaft deflection.

REDUCES NOISE AND VIBRATION – Because of the high efficiency design of the Simsite® Impeller, its light weight, its noise absorbing characteristics, and its precision machined design, noise and vibration are reduced in the pump.

Simsite® Impellers – perfect for retrofit and replacement applications

Simsite® Impellers are an ideal replacement for bronze, or other metallic impellers, especially in corrosive pumping applications. Because Simsite® is an inert material, electrolysis within the pump is reduced considerably. As metallic impellers corrode, they become unbalanced, causing premature wear on all other rotating parts. By replacing worn out parts with Simsite, the pump lasts longer and costs are reduced.

–Toward Polymeric and Polymer Composites Impeller Fabrication

–Wastewater Technology Fact Sheet: In-Plant Pump Stations

–Wastewater Technology Fact Sheet: In-Plant Pump Stations

–Manufacturing of Closed Impeller for Mechanically Pump ..

–Corrosion and failure of service water pump impeller snap rings

–Right Pump Impeller Design Changes to Improve

–Trim or Replace Impellers on Oversized Pumps

–Design of pump impellers using digital computer

–Submersible Multistage Centrifugal Pump for Versatile Testing