SIMS fiberglass reinforced composite pumps are centrifugal, single stage pumps, which are compliant to ANSI and ASME Standards. SIMS Fiberglass pumps are manufactured in fiberglass reinforced vinyl ester resin systems, which lends to their superior corrosion resistance.

SIMS Fiberglass Pumps are produced by molding technology. The fiberglass composite pumps and pump parts are manufactured in molds where reinforcing layers of glass fiber mat are arranged prior to the infusion of the resin. SIMS Fiberglass Pumps are available in a complete range of ANSI sizes.

The use of continuously interwoven glass fibers in layers of different weights and thickness allows Sims to reinforce the composite structure in the areas subject to the most mechanical stress and at the same time offers excellent chemical resistance.

The thermoset resin systems used are different from thermoplastic resin systems, because they do not breakdown under pressure or temperature and they cannot be re-processed once catalyzed. This superior process results in much better mechanical properties, thermal and dimensional stability, and longer life.

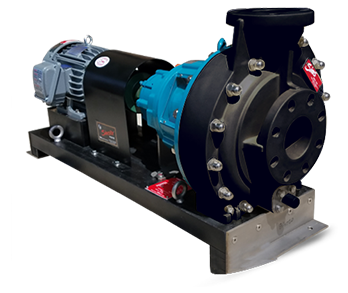

Coupled with a power frame (bearings housing) and flexible spacer coupling.

Close coupled, which is more compact and economical.

| FIBERGLASS RESIN | APPLICATIONS |

|---|---|

| V1G Standard Vinyl Ester Resin Compound | General purpose |

| V1C Vinyl Ester Resin Compound | Bleach applications |

| V1F Vinyl Ester Resin Compound | Fluoride applications |

| FIBERGLASS RESIN | APPLICATIONS |

|---|---|

| V1G Standard Vinyl Ester Resin Compound | General purpose |

| V1C Vinyl Ester Resin Compound | Bleach applications |

| V1F Vinyl Ester Resin Compound | Fluoride applications |

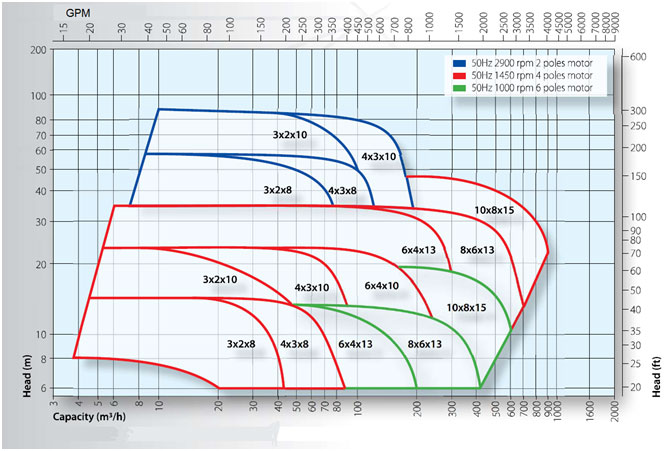

General Performance Curves 50 Hz

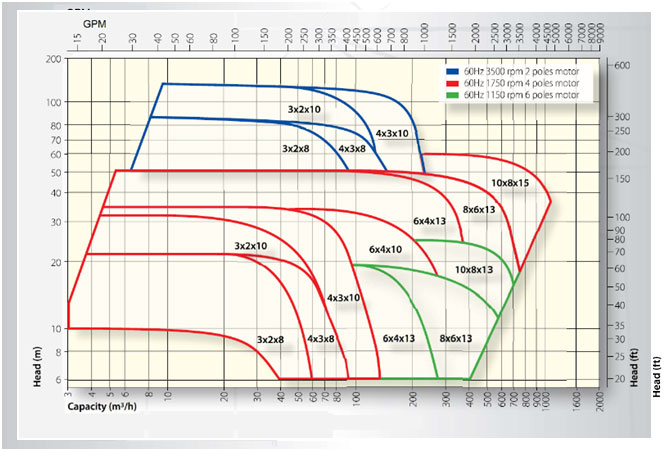

General Performance Curves 60 Hz

| MARKET | APPLICATIONS |

|---|---|

| Aquariums/Zoos | Saltwater |

| Chemical Process | Acids, Chemical Waste, Waste water |

| Desalination | Filtration, Seawater Intake, Chemical Transfer, Concentrated Brine |

| Electric Utilities | Coal Pile Run-Off |

| Electronics | Acids, Chemical Waste |

| Metal Finishing | Chromic Acids, Pickling Acids, Plating Solutions |

| Petrochemical | Acids, Chemical Waste |

| Pharmaceuticals | Organic Solvents |

| Pulp and Paper | Bleach |

| Mining | Abrasives, Corrosives |

| Scrubbers/Odor Control | Acids, Caustics |

| MARKET | APPLICATIONS |

|---|---|

| Aquariums/Zoos | Saltwater |

| Chemical Process | Acids, Chemical Waste, Waste water |

| Desalination | Filtration, Seawater Intake, Chemical Transfer, Concentrated Brine |

| Electric Utilities | Coal Pile Run-Off |

| Electronics | Acids, Chemical Waste |

| Metal Finishing | Chromic Acids, Pickling Acids, Plating Solutions |

| Petrochemical | Acids, Chemical Waste |

| Pharmaceuticals | Organic Solvents |

| Pulp and Paper | Bleach |

| Mining | Abrasives, Corrosives |

| Scrubbers/Odor Control | Acids, Caustics |

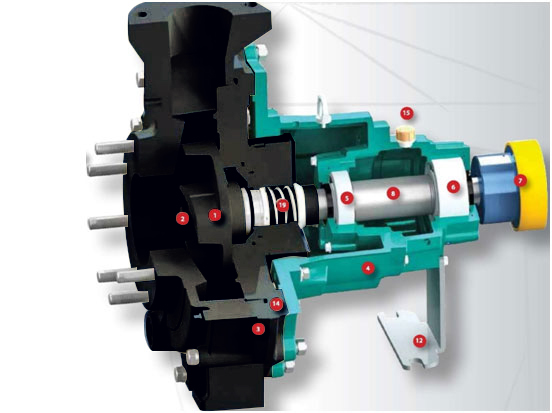

1- Impeller

Centrifugal, semi-open type with high efficiency vanes. Also available in an enclosed version. The impellers are available in Sims FRP or upgraded with Simsite® Structural Composite.

2- Impeller Nut

The impeller nut is a polyester part with a stainless steel core embedded in it when it is molded. The impeller nut is designed to lock the impeller permanently into position. It has a hexagonal shape compatible with a standard wrench.

3- Volute Casing and BackPlate

The volute casing is resin transfer molded into a single piece without joints and it is extremely resistant to chemical attack. The casing and back plate are designed to withstand high mechanical stress and are built for longevity.

4- Bearings Housing and Rear Flange

Cast iron parts produced by a mechanized process and epoxy coated. The support holds the bearing housing and the lubricant oil. The lantern ring, located in the intermediate position, connects the support to the rear casing flange.

5- Bearing: Pump Side

The bearing on the pump side has taper roller bearings to counter axial and radial thrusts and loads.

6- Bearing: Motor Side

The volute casing is resin transfer molded into a single piece without joints and it is extremely resistant to chemical attack. The casing and back plate are designed to withstand high mechanical stress and are built for longevity.

7-Flexible Spacer Coupling

Made of cast steel, it is a single piece with crown in a polymercomplete with a removable spacer to allow the pump to be pulled out for disassembly purposes.