Composite Impellers Produce Significant Lifecycle Savings

-

simsite

-

July 26, 2023

Up to 20 per cent of a pump’s energy consumption can be saved with the use of composite impellers, especially where the pump is required to work with a corrosive or erosive medium, according to figures released by Sims Pump Valve Co Inc. The company quotes a lifecycle saving of over US$192,000 for a 45kW (60hp) vertical in-line pump working in salt water, using a composite impeller as opposed to a metallic impeller.

With this kind of saving the capital outlay is only 9 per cent of the total lifecycle cost which is why the US Department of Energy, Europump, and the Hydraulic Institute have recently focused on pump lifecycle costs. The Department of Energy says that many centrifugal pumps may be less than 50 per cent efficient but have the potential to improve by 20-30 per cent through various upgrades and system changes. Energy savings from the composite pump impellers are produced by two sources. The first is from the composite material being lightweight, requiring less energy to move the mass of the impeller. The second comes from the fact that they do not corrode so as a consequence do not change the design characteristics of the pump’s impeller.

When the metallic pump parts begin to wear from corrosion, efficiency drops drastically. This drop in efficiency not only has a significant impact on energy consumption but also increases the cost of maintenance. The life of the pump can be reduced to months instead of years as originally intended.

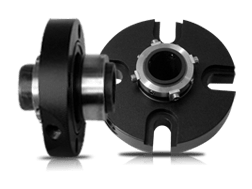

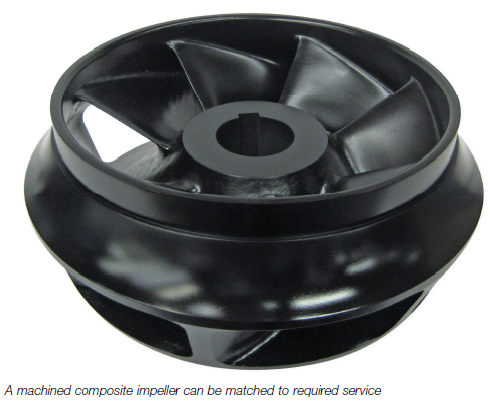

Machining enables the composite impeller to be optimized for the service in which the pump is designed. Using this production method also gives perfect mechanical and hydraulic balance due to the accuracy of the vane passages through the impeller, Sims says. The company adds that since these impellers are corrosion resistant to most liquids, they do not become imbalanced even after years of service, and this reduction in vibration also translates into higher efficiency and a reduction in energy consumption.

Composite impellers are only 15 per cent of the weight of traditional metallic materials. The lower weight not only reduces startup load but also reduces shaft deflection. This allows the rotating element to run with tighter clearances between the rings and the impeller giving the increases in efficiency and the reduction energy consumption and maintenance costs that are claimed.

Briefing: Composite Materials

Composite materials comprise two or more different materials combined to form a superior material to the originals. This generic term has now become linked with glass or carbon fibre, where the fibres carry the bulk of the load and the resin is used to bind the fibres together. The different types of fibre can be grouped into organic, inorganic and metallic.

Manufacturing techniques are important when the raw material is turned into an actual object. The resin provides chemical and thermal properties, gives chemical resistance and transfers the load to and between the fibres. The reinforcing fibre determines the mechanical properties, provides mechanical strength, disperses the load and gives dimensional stability to the completed structure. The fibre can also be cut or chopped, continuous or continuous and inter-woven – each will provide different strength characteristics.

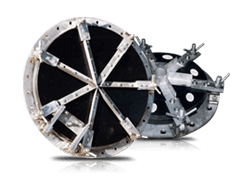

The final raw product can then be made into components and objects ranging from parts of cars and aeroplanes to marine pump impellers and strum boxes. A range of techniques are used from compression moulding and vacuum induced moulding to machining solid blocks.

Continuous fibres provide the highest strength and flexibility available on the market today. As a heavy-duty structural composite its characteristics can be tailored to the patented process thus accommodating the required structural strength of the parts being manufactured.

Impellers produced by Sims are made from a structural composite where the fibres are not chopped, cut, or macerated but are continuous and interwoven. They have the mechanical strength of metal, and have self-lubricating qualities embedded in them eliminating the risk of seizing and galling. Furthermore, these engineered composites have extremely smooth surfaces with an excellent finish and a low coefficient of friction thereby increasing efficiency and reducing energy consumption, the company says.

Simsite is a patented structural composite material offered exclusively by the Sims Pump Valve Co. It is a graphite combination-fibre continuously interwoven bi-directional or tridirectional, reinforced composite with phenolic/epoxy thermoset resin.

“All of our Simsite structural composite pumps and pump parts are machined on five to eight-axis robotic machining centres and with the technology available today, the impeller design and the pump design can be optimized prior to machining or manufacturing through the use of finite element analysis and computational fluid dynamics programs,” says John A Kozel, president of Sims Pump Valve Co. “All Sims products are completely machined, they are not cast or moulded.”

Mr Kozel says that many of these impellers and casing rings have been used successfully since 1955, in the marine, navy, waste water, industrial and chemical markets. Structural composite impellers, like Simsite impellers, have outlasted and outperformed products manufactured from bronze, stainless steel,

duplex steel, monel, and even titanium.

Pumps are purchased to cover a specific role in moving a mass of fluid to fairly tight design characteristics. However economies of scale and limits in the cost of production mean that the

pump manufacturers produce pumps to cover a range of performance envelopes. Therefore the pump that has been purchased to match a specific design may not operate at its best efficiency point due to the exact requirements of any one system. Consequently when the pump is operated not only does it require excess energy to carry out the basic design function but it will also produce excessive noise and vibration creating shaft oscillation, cavitation, premature wear and failure of the mechanical seals, bearings, rings,

sleeves and impellers. In extreme cases, the pump shaft will break.

This problem can be overcome by optimising the pump performance to the requirements of the service. Sims specialises in solving balance, cavitation, corrosion, electrolysis, erosion and radial thrust problems by upgrading existing pumps and impellers to Simsite structural graphite composite components. And it can manufacture obsolete parts for any centrifugal pump with quick deliveries and focuses on life

extension says Mr Kozel.

Pump upgrades, using composites, are not only designed to improve performance and reduce maintenance and repair issues but they also improve efficiency, extend pump life and reliability. Pump upgrades prevent expensive products from deteriorating; they can even prevent pump leaks that may result in costly cleanups and fines from regulatory agencies. In most cases, the reduced downtime eliminated by the pump upgrade outweighs all other benefits.

It is often difficult to raise the necessary capital for upgrades, however, the payback is extremely short. The resulting savings from the upgrades releases funds that are otherwise wasted on energy and more expensive repairs at a later date. In almost all cases, the incremental costs of upgrades are minimal when compared to the loss in downtime and expensive repairs according to Sims.

The company can upgrade existing metallic pumps and impellers and replace them with structural graphite composite pumps and pump parts, which last much longer and offer better operating efficiencies. “Sims specialises in solving balance, cavitation, corrosion, electrolysis, erosion and radial thrust problems by upgrading existing pumps and impellers to Simsite structural graphite composite components,” Mr Kozel says.

Resources

–Toward Polymeric and Polymer Composites Impeller Fabrication

–Wastewater Technology Fact Sheet: In-Plant Pump Stations

–Wastewater Technology Fact Sheet: In-Plant Pump Stations

–Manufacturing of Closed Impeller for Mechanically Pump ..

–Corrosion and failure of service water pump impeller snap rings

–Right Pump Impeller Design Changes to Improve

–Trim or Replace Impellers on Oversized Pumps

–Design of pump impellers using digital computer

–Submersible Multistage Centrifugal Pump for Versatile Testing