Upgraded Rotor Dynamics for Pump Shafts – Reduce Shaft Deflection & Vibration

-

simsite

-

August 10, 2023

Pump Vibration and Shaft Deflection of any Rotating Element is directly proportional to the diameter and length of the shaft, (L/D) the position of the impeller on the shaft (overhung or centered), mechanical and hydraulic balance of the impeller, and where the pump is operating on the pump curve. If the pump is not operating at the Best Efficiency Point (BEP) it is subject to recirculation cavitation and high radial loading, which will cause loss of performance, efficiency and very high vibrations and shaft deflections.

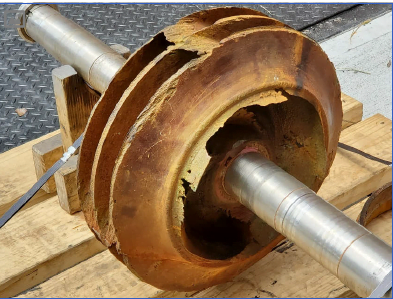

Whether the pump is Horizontal, or Vertical, the weight, and inherent mechanical & hydraulic imbalance, of cast impellers (especially cast metallic impellers) even when they are brand new sets up a condition for premature bearing, ring, mechanical seal and motor failure.

Like the Pendulum on a clock, the impeller acts like a weight at the end of the shaft and starts to wobble, or deflect. Any Corrosion, Erosion, or Cavitation increases the Pendulum Effect Problem and substantially increases shaft deflection, and pump vibration! The motor bearings cannot hold the stresses that are set up by the Pendulum Effect and the Mechanical Seals, Sleeves, Bushings, Motor Bearings, and Motor fail prematurely. In extreme cases, the shafts break.

Bearing and mechanical seal failures are directly proportional to the rotor weight, speed, the amplitude of the mechanical imbalance, as well as the radial loading on the shaft as a result of hydraulic imbalance.

Often Customers complain about Mechanical Seal Failures, or Bearing Failures, and even Motor Failures. What most Customers do not realize is that they DO NOT have a Mechanical Seal Problem, or a Bearing Problem or a Motor Problem; rather, they have a “Hydraulics Problem” caused by Mechanical or Hydraulic Imbalance, Radial Thrust, or the Improper Design, Repair, or Manufacture of the Impeller!

All of these problems can be eliminated by upgrading to SIMSITE® Structural Composite Carbon Fiber Impellers & Casing Rings!

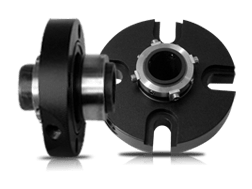

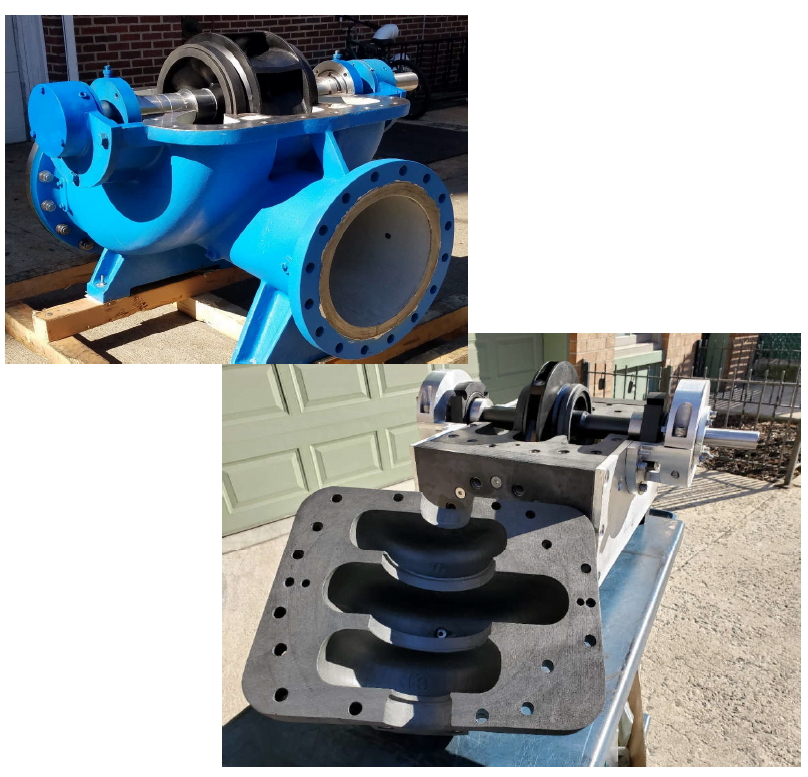

The combination of our new patented SIMSITE® Carbon Fiber split stabilizing Bushing with our SIMSITE® Structural Carbon Fiber Impellers & Casing Rings completely changes the rotor dynamics FOR ANY ROTATING ELEMENT. The result is that shaft deflection and vibration are minimized.

The reasons for this are as follows:

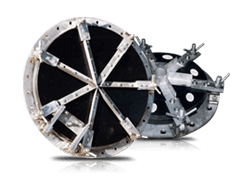

1) Less Weight – SIMSITE® Patented Structural Composite Carbon Fiber Impellers, Rings, and Bushings are 85% Less Weight when compared to Bronze, or Stainless Steel, and even lighter when compared to duplex stainless steel! This reduces start-up load and shaft deflection.

2) Perfect Balance both Mechanically and Hydraulically — Imbalance and the “pendulum effect” are eliminated, because SIMSITE® Impellers are machined on 5 to 8 axis machining centers from one center position — they are NOT cast or molded like metallic impellers. As a result, SIMSITE® Impellers are balanced both mechanically and hydraulically and since they do not corrode they remain balanced for the life of the impeller!

3) SIMSITE® Stabilizing Bushings – The patented SIMSITE® Split Stabilizing Bushings offers superior shaft support and mechanical seal protection. They also protect the mechanical Seals from movement and debris!

4) No Corrosion – SIMSITE® Patented Structural Composite Carbon Fiber Products do not corrode in Seawater, Sewage, Waste Water, River Water, or Chlorinated Water so performance, balance, and shaft deflection will not be affected!

5) Cavitation is Eliminated, or Minimized – Because SIMSITE® Impellers are machined and not cast or molded, they are designed and engineered specifically for the best efficiency point eliminating hydraulic imbalance, radial loading, vibration, and shaft deflection!

Cast, or Molded impellers are not designed, or engineered for the “Specific Operating Conditions” of the pump in service. Therefore, most pumps are not operating at the Best Efficiency Point (BEP) where radial loads, shaft deflection and vibration are negligible. Rather, they are operating “Out” on the performance curve, or “Back” on the performance curve away from the Best Efficiency Point. The farther away from the Best Efficiency Point (BEP) they operate, the higher the radial loads causing excessive vibration, shaft deflection, and premature bearing, seal, ring, motor and even shaft failures!

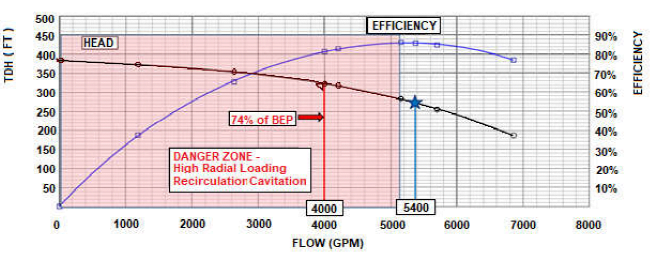

This Pump Curve above shows a pump that was designed to operate at 5400 Gallons Per Minute (GPM) at 275 Feet of Head (FT) at 1750 RPM. This point is called the Best Efficiency Point (BEP) – the point at which the pump and impeller are designed to operate most efficiently. Instead, the pump was operating back on the pump curve — 26% away from the best efficiency point at 4000 GPM at 360 FT of Head at 1750 RPM. Operating at 74% of BEP put this pump into the Danger Zone for Recirculation Cavitation, which caused tremendous Vibration, Shaft Deflection, a loss of Efficiency, an increase in the Brake Horse Power (BHP) and total pump failure.

Solution:

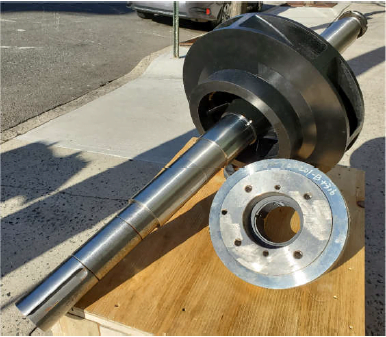

The solution is to use a SIMSITE® Impeller that will be designed specifically for the Operating Point making the Operating Point the Best Efficiency Point. It is not good enough to manufacture an impeller that will reach this point – the design point has to be the best efficiency point to maximize performance and efficiency and to eliminate vibration and shaft deflection.

The SIMSITE® Structural Composite Carbon Fiber Impeller & Casing Ring Set will be light weight, and 100% machined from solid blocks of the patented SIMSITE® composite which does not corrode, cavitate, or go into an imbalance. These machined SIMSITE® structural composite Impellers are 85% less weight than bronze, or stainless steel impellers and rings and they do not go into an imbalance because the vane passageways and exit ports are all equally spaced as a result of being machined.

SIMSITE® Structural Composite Impellers are engineered and designed to operate at the Customer’s Operating Point (OP), making the Operating Point the Best Efficiency Point (BEP) Installing impellers that operate at the Best Efficiency Point is extremely important, because not only does it make the pump much more efficient, but it substantially reduces radial loads, shaft deflection, and eliminates hydraulic and mechanical imbalance! This allows the pump to operating substantially longer without premature failure of the bearings, rings, bushings, sleeves, mechanical seals, and motors.

SIMSITE® Structural Composite Carbon Fiber Pumps, Impellers & Casing Rings, Sleeve Bearings, and Split Stabilizing Bushings pay for themselves over and over again because they substantially reduce repair, maintenance and energy expenses!

By John A. Kozel, the President of Sims Pump Company, Inc.

Resources

–Toward Polymeric and Polymer Composites Impeller Fabrication

–Wastewater Technology Fact Sheet: In-Plant Pump Stations

–Wastewater Technology Fact Sheet: In-Plant Pump Stations

–Manufacturing of Closed Impeller for Mechanically Pump ..

–Corrosion and failure of service water pump impeller snap rings

–Right Pump Impeller Design Changes to Improve

–Trim or Replace Impellers on Oversized Pumps

–Design of pump impellers using digital computer

–Submersible Multistage Centrifugal Pump for Versatile Testing