What are the Best Pumps to Purchase?

-

simsite

-

September 20, 2023

AT THE END OF THE DAY IT IS ALL ABOUT LONGEVITY, RELIABILITY, EFFICIENCY AND PERFORMANCE!

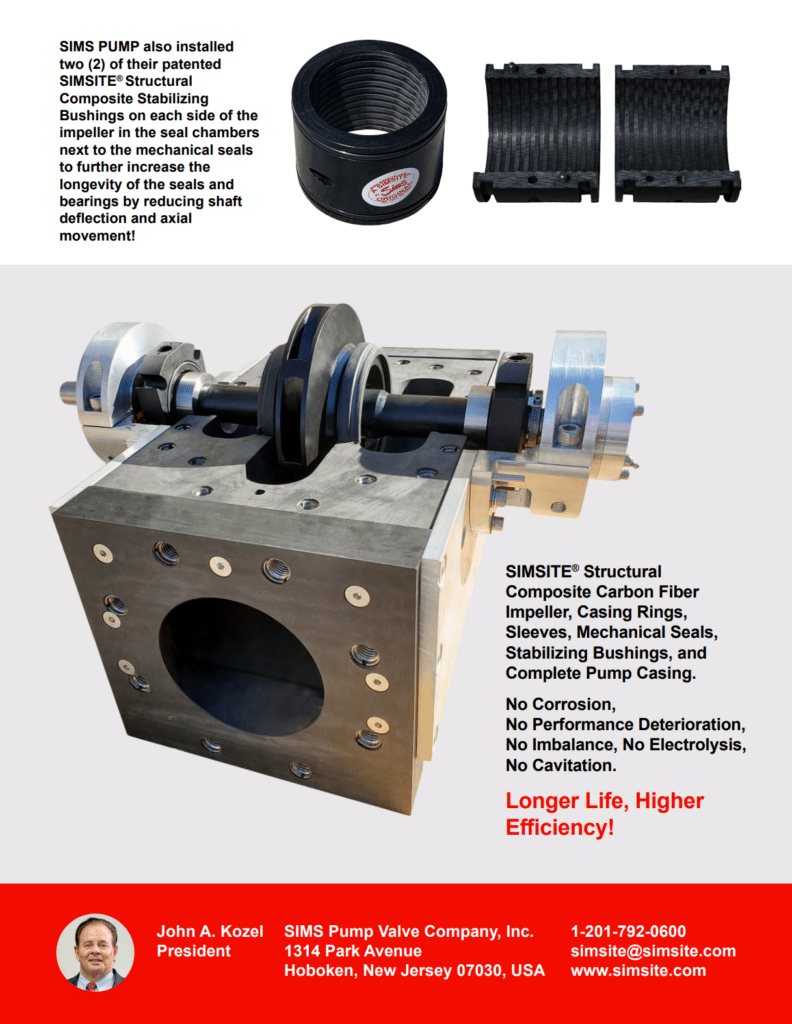

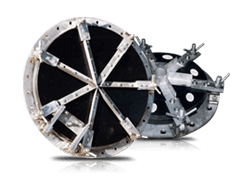

The best type of Centrifugal Pumps to Purchase are pumps that have specified SIMSITE® Structural

Composite Impellers and Casing Rings, because these pumps are “Engineered Specifically for the Customer’s Operating Point!

In order to have a good human body, you must have a good “heart.” The same principle is true with centrifugal pumps. They must have a good “heart,” which in this case is the “impeller.” Without a great

Impeller the pumps will be plagued with problems, which will cost the Customer stress, downtime, and

tremendous expenses!

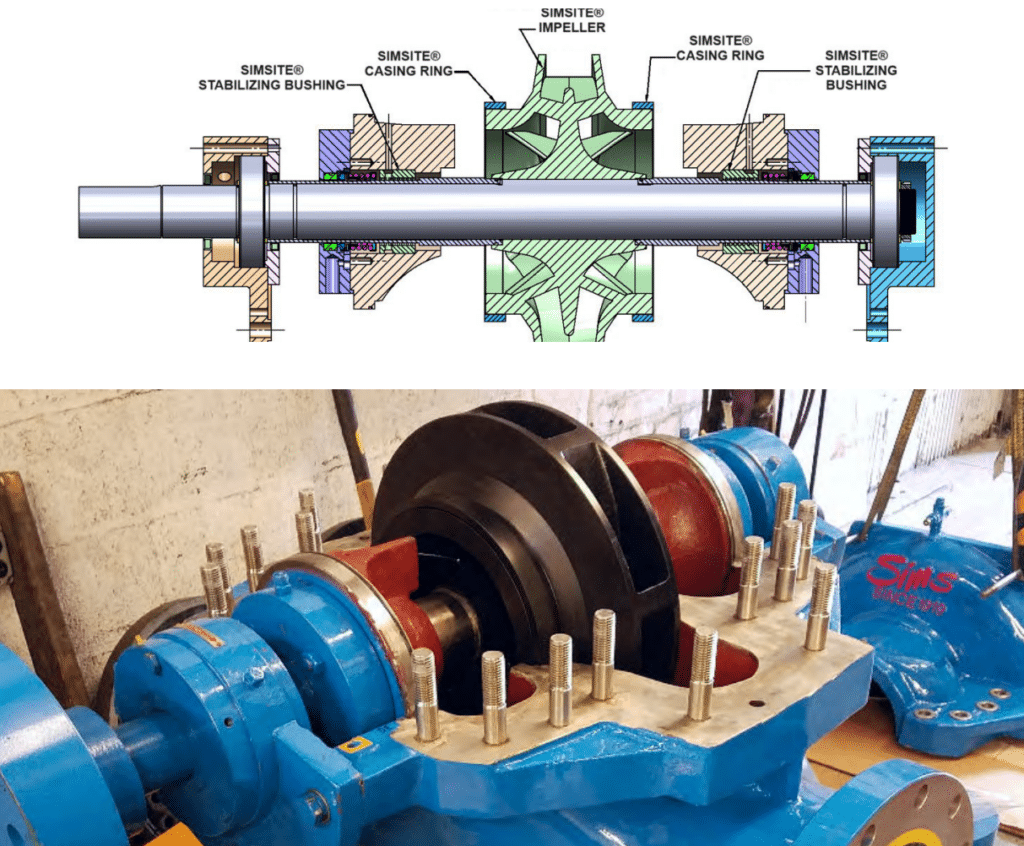

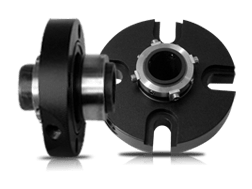

The advantage of pumps with SIMSITE® Impellers is that they are machined on 5 to 8 axis machining

centers as opposed to being cast or molded. SIMSITE® Impellers & Rings are 100% machined on the inside as well as the outside from a solid blocks of the patented SIMSITE® Structural Composite from one

center position; and therefore, are balanced both mechanically and hydraulically, and remain balanced for

the life of the impeller. All the vanes are within .001 of each other. This balance means less shaft deflection and a much longer life for the bearings, bushings, mechanical seals, sleeves, motor, and all other rotating parts!

A much better alternative for any Customer with a centrifugal pump is to order a pump with Structural

SIMSITE® Composite Impellers and Casing Rings, which are far superior to cast, molded, or metallic

products, and offer a much longer life-cycle for the Customer. See the reasons to specify SIMSITE® Impellers & Rings on the next page.

- SIMSITE® Impellers & Casing Rings, never corrode in Seawater, Sewage, Waste Water, River Water, Chlorinated Water, and are excellent in most chemical applications! Since SIMSITE® Products do not corrode, they do not suffer from performance deterioration, or go into an imbalance causing premature pump failure!

- SIMSITE® Impellers & Rings are 85% less weight than metallic impellers & rings, which means less shaft deflection, and a much longer life for Bearings, Mechanical Seals, Sleeves, Rings, and Motors!

- SIMSITE® Impellers are 100% machined on the inside as well as the outside; and therefore, are balanced both mechanically and hydraulically, and remain balanced for the life of the impeller. This balance means less shaft deflection and a much longer life for the bearings, mechanical seals and all other rotating parts!

- SIMSITE® Impellers & Rings are specifically designed & engineered for the Customer’s performance requirements. This enables the Operating Point to be the Best Efficiency Point (BEP. This means that the pump does not suffer from high radial loading, cavitation, or shaft deflection, which substantially increases pump longevity and reliability!

- SIMSITE® Impellers & Rings are more efficient than metallic Impellers & Rings, which increases efficiency, reliability, longevity, and reduces the cost of operation of the pumps!

- SIMSITE® Impellers & Rings are “Inert” and therefore will not support Electrolysis or galvanic corrosion like metallic impellers. Because they are “Inert,” the entire pump will last much longer!

- SIMSITE® Casing Rings prevent “Pump Wash Out” in the landing ring areas, which enables the pump casing to last much, much longer in all environments, but especially in corrosive environments!

Many pump companies offer cheaper pumps with cheaper metallic solutions, and it is often tempting to purchase these items, but like everything in life, nothing is for free. When these cheaper pumps do not last, because they cavitate, corrode, deteriorate, lose performance and efficiency, you do not save money; rather, you lose money!

The first time you have to overhaul your pump because of a leaking seal, bad bearing, loss of performance, or a vibration/imbalance problem you are looking at a substantial investment!

Upgrading, or Specifying Pumps with SIMSITE® Impellers & Casing Rings Eliminates Corrosion, Cavitation, Improves Longevity, Reliability, Energy Efficiency and saves money! Simsite® Impellers & Rings are the best solution!

Pumps with SIMSITE® Impellers & Rings are not “Production Pumps;” rather, they are “Engineered Pumps,” which are designed, engineered, and manufactured for longevity, performance, high efficiency and reliability!

For example, Yannis Karavia LLC (Dorchester Shipyard was looking for a Main Sea Water Pump for their fishing vessels. In the past, they had used a multitude of “Production Type” Pumps from major pump manufacturers in Europe, Asia, and the United States.

Unfortunately, they were plagued with problems — Mechanical Seals and Bearings were failing prematurely and even shafts were sometime breaking from high radial loading. Every time a pump failed,

they lost production and money. Totally frustrated, they came to SIMS PUMP.

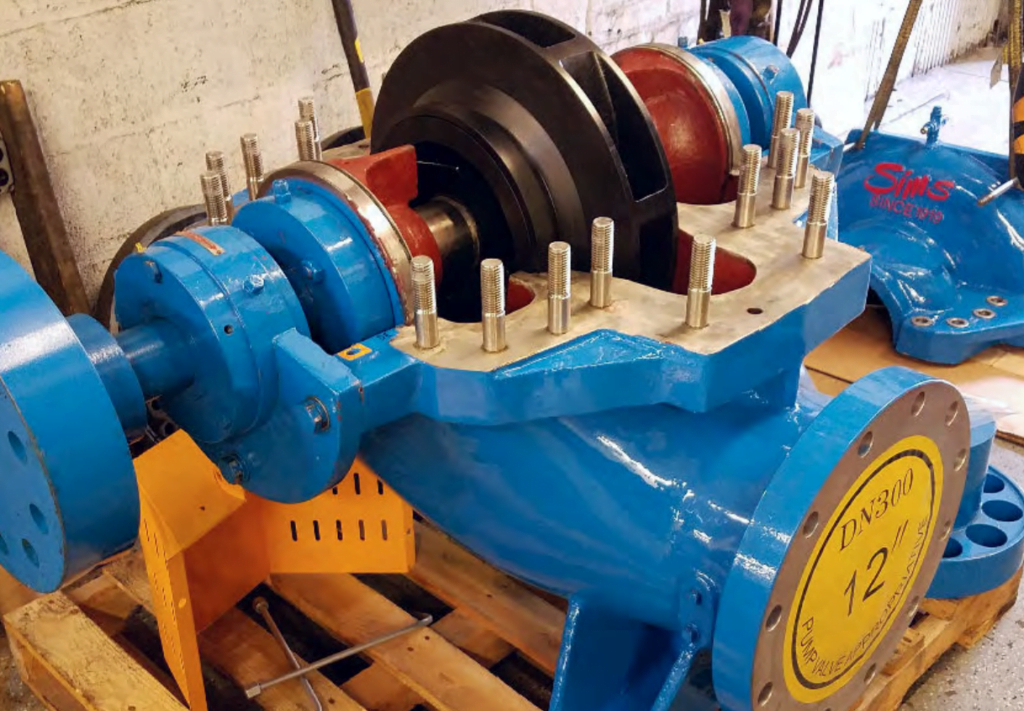

SIMS PUMP designed a 12″×10″×21″ double suction, horizontally split, pump casing from type 316

Stainless Steel with their patented SIMSITE® Structural Composite Impeller & Casing Ring Set designed

specifically for the vessel’s operating point, which made their operating point the best efficiency point

(BEP. This eliminated the high radial loading and shaft deflection problems that the old production pumps

were experiencing and enabled the mechanical seals and bearings to last much longer! Not only did

these new SIMS PUMPS operate much longer, but they also operated at a higher efficiency and they also

eliminated the shaft breaking problems.